Constant-Current LED Drivers: Superior Electrical, Thermal And EMC Characteristics Attractive In Low-Power Applications

By Nexperia

While high-power LEDs need complex driver schemes and thermal management, the vast majority of lighting applications can operate with a simpler driver circuit, since they use LEDs operating at currents far below 500mA. LEDs operating at a low current can use a very simple and robust constant-current LED driver which is in essence a simple linear regulator. They are easy-to-use, reliable, cheap, and have no effect on EMC performance.

This Design Note explains the constant-current LED driver, and describes the simple power, thermal and packaging issues to consider when integrating it into lighting systems. The article refers to drivers with the suffix NCR: these products are available from Nexperia. They are used in interior and exterior automotive applications such as door handles, the dashboard, number plate lights, indicators, and rear lights.

The components of A Constant-Current LED Driver

Fig. 1: LED driver topologies - low-side using NPN and high-side using PNP

Figure 1 shows the topology and schematic of constant-current LED drivers. A driver consists of a Bipolar Junction Transistor (BJT), two diodes, and two resistors. In Figure 1 a) and b), NPN BJTs operate as a low-side driver, while in c) a PNP BJT operates as a high-side driver.

One of the resistors defines the minimum output current; the other tunes the bias voltage, and plays an important role in the Enable function. Both the low-and high-side drivers have an Enable pin. This part draws a current of around 1-2mA at the Enable pin, so it can easily be driven by the output from a microcontroller or a logic device, as shown in Figure 1 b). This is a convenient arrangement when controlling the LEDs’ output with the PWM output from an MCU.

The high-side constant-current driver has an Enable pin which is connected to ground, and can be turned off by disconnecting it. In practice, this is performed using a Resistor-Equipped Transistor (RET) or MOSFET, as illustrated in Figure 1 c).

Evaluating The Electrical Performance Of A Constant-Current LED Driver

The output current from the constant-current LED driver is adjustable by an external resistor, Rext. Some types are tuned to commonly used currents using an internal resistor. As they do not need an external resistor, they are available in three-pin packages.

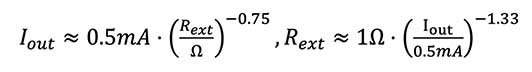

When an external resistor is to be connected, it will be in parallel to the internal resistor, thereby lowering the effective resistance. The low-side NCRx2xx constant-current drivers, which use an NPN transistor, have an internal resistor of 95Ω. The output current supplied by the driver can be estimated as:

Using these formulas, setting up the LED driver is easy and quick. The value of the external resistor should high enough to limit the current, and thus avoid damaging the driver. When the external resistor is smaller than the internal, most of the current will flow through the external resistor.

The dimming capability of the NCR321Z and NCR4x1Z drivers can be assumed to be linear, which means that the averaged output current and the duty cycle show a linear relationship up to a recommended maximum frequency of 10kHz and beyond.

The minimum voltage drop across a constant-current driver is about 1.4V. Below this voltage, linear regulation does not work properly. Above it, the voltage drop across the constant-current driver dynamically adjusts to supply the desired output current. In low- and high-side configurations, the output voltage Vout is calculated as Vout = VCC – VLED, where VLED is the voltage at the LEDs and VCC is the supply voltage.

Constant-current LED drivers are used when the LED’s brightness should be independent of the supply voltage to some degree. For example, the 12V power supply in a car can fluctuate between 11V and 15V during normal operation. If the desired drive current and the voltage drop across the LEDs are known, the minimum possible supply voltage can be calculated by adding the voltage drop across the driver to the voltage at the LEDs. The maximum allowed voltage is governed by the maximum permitted voltage drop across the driver’s output, or the total power dissipation. Hence the allowed operating range, if datasheet limits are not exceeded, can be specified as:

In addition, the voltage margin can be increased by reducing the output current. Placing two or more constant-current drivers in parallel, as illustrated in Figure 2, effectively doubles or triples the current. Using this method, current exceeding the capability of a single driver can be supplied, or a smaller current per driver can be used to increase the voltage margin.

When driving constant-current drivers in parallel, the accuracy of the external resistors is the most important factor for the symmetry of the output currents of the individual drivers. Figure 3 illustrates the voltage margins depending on the output current for single and parallel drivers in SOT457, SOT223, and DFN2020D-6 packages.

Fig. 2: Parallelization of two or more current-source LED drivers to increase the LED current

Fig. 3: Voltage margin of single and parallel drivers in various packages SOT457 NCR42xU or NCR32xU in SOT457; NCR42xZ or NCR32xZ in SOT223; and NCR32xPAS in DFN2020D-6.

Evaluating Thermal Performance

The Nexperia range of constant-current LED drivers is available in five different packages which have different power dissipation characteristics (see Figure 4).

The SOT23 package is suitable for low-current and low-power applications which are restricted to a small board area. By contrast, the SOT223, the largest package, is well suited to applications consuming up to 1,250mW.

The drivers in a DFN package offer good thermal performance at a maximum current up to 300mA and power up to 700mW, and good reliability overall.

Fig. 4: Thermal ratings and maximum values for electrical parameters the the five package styles in which Nexperia constant-current LED drivers are available. 1 Device mounted on an FR4 PCB, four-layer copper, tin-plated and standard footprint.

LED drivers are also available in compact DFN packages, offering savings in board footprint of up to 68% compared to the SOT23 package. Their very good thermal performance is illustrated in the simulations in Figure 5.

Fig. 5: Simulation of the thermal performance of a constant-current LED driver in a DFN1110(B)D-3 package (right) compared to SOT23 (left). The simulation assumes a dissipated power of 250mW.

EMC Behavior

Compliance with EMC regulations is increasingly difficult in automotive applications due to the increasing density of power electronics and high-speed interconnects in the car interior. The use of constant-current LED drivers can improve the overall EMC performance of the vehicle substantially, easing the task of achieving EMC compliance.

When the Enable pin is driven by a DC voltage, in theory no emission will be expected. In the presence of external electromagnetic waves, however, the Enable pin can be disturbed, and this can have an impact on the operation of LED lights. This effect can be prevented by placing a capacitor as close as possible to the driver. The capacitance value should be related to the frequency at which the disturbance is expected.

When the driver’s Enable pin is driven by a digital PWM signal, Nexperia recommends that the switching frequency should be limited to a maximum of 10kHz. If the Enable signal is rectangular, higher harmonic frequencies should also be taken into account.

Fig. 6: Fourier amplitudes (first 10 harmonics) of current-source LED drivers in PWM mode with a switching frequency of 10kHz, compared to typical LED boost or buck drivers which have a typical switching frequency of 400kHz or 2MHz.

Figure 6 shows that only the tenth harmonic of the constant-current LED driver’s output in PWM mode even gets close to the 125kHz frequency. Contrast this with other LED driving solutions such as switched boost or buck converters, in which the typical switching frequency ranges from several hundred kHz to a few MHz. With these systems, emission control is difficult, because several important frequency bands such as the AM radio, FM radio or digital DAB radio can be badly affected by the higher harmonic frequencies, especially in the presence of internal resonances.

Overall, therefore, compared to conventional boost or buck topologies, current-source drivers provide markedly better EMC performance even when operating in PWM mode.