More Information on Ceramic Capacitor...

What is a Ceramic Capacitor?

A ceramic capacitor is a fixed-value capacitor in which ceramic material acts as the dielectric. It is constructed of two or more alternating layers of ceramic and a metal layer acting as the electrodes. The composition of the ceramic material defines the electrical behavior and therefore applications.

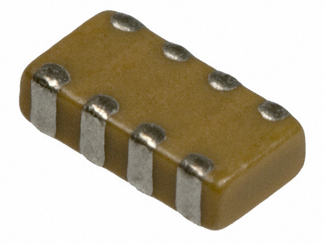

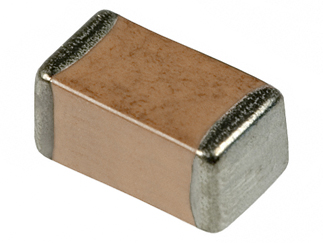

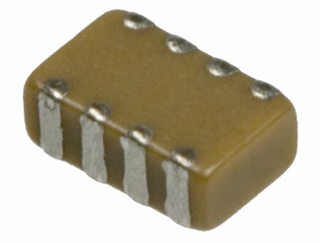

The most used capacitors are disc capacitors and especially multilayer ceramic capacitors or multi-layer chip capacitor MLCCs .

Ceramic Capacitor- Characteristics

- Accurate tolerances and precisions- Ceramic capacitors are mainly used for high stability performances and where in devices with low losses. These devices provide very accurate results and also the capacitance values of these capacitors are stable with respect to the applied voltage, frequency and temperature.

- Advantages of small size- In cases of packing densities for high components are required, these devices are of great advantage when compared with the other capacitors. For example, a “0402” multi-layered ceramic capacitor measures about 0.4 mm x 0.2 mm.

- High power and high voltage- The ceramic capacitors are manufactured in such a way so that it can survive higher voltages and such capacitors are power ceramic capacitors. These capacitors are much larger than those used on PCBs. They also have specialized terminals used for safer connection of high voltage supply. The Power ceramic capacitors tolerate voltages ranging from 2kV- 100 kV.

Ceramic capacitors are divided into three application classes:

Class 1 ceramic capacitors offer high stability and low losses for resonant circuit applications.. They are very accurate and the capacitance value is stable in regard to applied voltage, temperature and frequency.

The NP0 series of capacitors has a capacitance thermal stability of ±0.54% within the total temperature range of -55 to +125 °C.

Tolerances of the nominal capacitance value can be as low as 1%.

The common compounds used as the dielectrics are magnesium titanate for a positive temperature coefficient, or calcium titanate for capacitors with a negative temperature coefficient. Using combinations of these and other compounds it is possible to obtain a dielectric constant of between 5 and 150.

Also temperature coefficients of between +40 and -5000 ppm/C may be obtained.

Class 1 capacitors also offer the best performance with respect to dissipation factor. This can be important in many applications. A typical figure may be 0.15%. It is also possible to obtain very high accuracy (~1%) class 1 capacitors rather than the more usual 5% or 10% tolerance versions. The highest accuracy class 1 capacitors are designated C0G or NP0.

Class 2 capacitors have a high capacitance per volume and are used for less sensitive applications.

- Temperature range: -50C to +85C

- Dissipation factor: 2.5%.

- Accuracy: average to poor

Class 2 capacitors offer better performance with respect to volumetric efficiency. They are normally used for decoupling, coupling and bypass applications where accuracy is not of prime importance.

Class 3 ceramic capacitors offer a still high volumetric efficiency at the expense of poor accuracy and stability and a low dissipation factor.

They are also not normally able to withstand high voltages.

The dielectric used is often barium titanate.

- Will change its capacitance by -22% to +50%

- Temperature range of +10C to +55C.

- Dissipation factor: 3 to 5%.

- It will have a fairly poor accuracy (commonly, 20%, or -20/+80%).

As a result, class 3 ceramic capacitors are typically used as decoupling or in other power supply applications where accuracy is not an issue.

Ceramic capacitors are available now in three main types although other styles are available:

- Leaded disc ceramic capacitors for through hole mounting which are resin coated

- Surface mount multilayer ceramic capacitors MLCCs

- Specialist microwave bare leadless disc ceramic capacitors that are designed to sit in a slot in the PCB and are soldered in place.

SMD / SMT ceramic capacitors

The vast majority of ceramic capacitors that are used today are in the form of surface mount technology devices - SMT.

SMD / SMT ceramic capacitors are shaped in the form of a rectangular block or cuboid. The capacitor itself consists of the ceramic dielectric in which a number of interleaved precious metal electrodes are contained. This structure gives rise to a high capacitance per unit volume.

Ceramic Capacitor Package Designations

| Package designation | Size (mm) | Size (inches) |

| 1812 | 4.6 x 3.0 | 0.18 x 0.12 |

| 1206 | 3.0 x 1.5 | 0.12 x 0.06 |

| 0805 | 2.0 x 1.3 | 0.08 x 0.05 |

| 0603 | 1.5 x 0.8 | 0.06 x 0.03 |

| 0402 | 1.0 x 0.5 | 0.04 x 0.02 |

| 0201 | 0.6 x 0.3 | 0.02 x 0.01 |

Applications for ceramic capacitors

The applications of ceramic capacitors includes transmitter stations, induction furnaces, high voltage laser power supplies, power circuit breakers, high density applications, printed circuit boards, DC to DC converters, etc.

These capacitors are also used as general purpose capacitor and are also used across the brushes of the DC motors in order to minimize the RF noise.