FTM / Power & Power Management / Future Electronics — Skilled Electronics Engineers Enable Your Product Design Success

By Martin Bernier, Hugo Letourneau, Denis Ouellette, Hongtao Diao

Future Electronics SDC

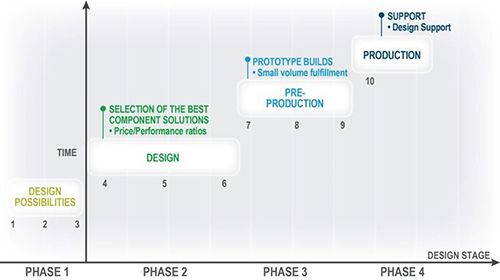

Future Electronics’ System Design Center (SDC) is a team of seasoned electronics engineers, in the field of hardware circuit design and software development. Their mission is to enable customers’ success by providing customized solutions, and to fast-track them to production from the early phases of their product designs.

The System Design Center hardware design team has extensive circuit design experience and a wide knowledge base in the field of hardware engineering. They cover high-speed digital design, high-precision mixed-signal and analog circuitry, as well as wireless RF, NFC, and wired communications. In addition, they have extensive knowledge in power supplies, power management and motor control. The SDC engineering group has everything covered.

Complementary to our hardware design services, the SDC software development team possesses deep knowledge and vast coding expertise. This allows these engineers to provide fully integrated solutions which further accelerate time to market.

Drawing on extensive experience in the latest development software and tool sets, the SDC engineering software team is well equipped. They help customers with firmware and software development of applications, drivers, board support packages and graphical user interfaces, as well as mobile apps for iOS and Android platforms and cloud computing platform interface designs.

Share This

Get access to the latest product information, technical analysis, design notes and more

Get in touch with our experts for more information!

Future Electronics SDC Engineers offer broad knowledge of suppliers’ electronic components. They have rich design expertise from large and complex projects to small and high-density systems. They are experienced in firmware and software development, and have privileged access to Future Electronics’ worldwide network of technology specialists. The SDC’s team of hardware and software engineers is not only able to handle any product development challenge involving circuit design, schematic/PCB layout, firmware/software development as well as production engineering support, but they are also able to enhance customers’ new products and accelerate their time to market.

Over the past 20 years, the Future Electronics SDC has helped numerous customers to accelerate their product introductions to the market. Application examples include:

The Future Electronics System Design Center provides substantial advantages to customers. From single boards to complete systems; individual modules to network-connected mobile applications for the industrial IoT, here are the benefits:

The Future Electronics SDC is fully equipped to help customers in every phase of electronics design. Some of the engineering services provided by the SDC include:

The Future Electronics SDC also develops industry-leading reference designs and development platforms for various new technologies and applications. They also work closely with customers on customized solutions.

Faraday is a reference platform which demonstrates current sensing using various technologies. It showcases integrated Hall effect current sensors which measure up to 25 A/60 V dc on two independent pass-through channels. The platform also demonstrates resistive current monitoring sensor ICs for measuring up to 5 A/20 V dc on a USB Type-C® pass-through channel, and up to 300 mA/5 V on a USB Type-A output port.

The Faraday board features an OLED display, a USB-to-UART interface to a terminal, and a capacitive sensing keypad. It is a ready-to-use all-in-one acquisition and analysis evaluation tool for voltage, current and power monitoring.

Scale-It is an easy-to-use weight scale development platform for measuring weights up to 100 g, and displaying the results on an OLED display.

It features a DSP-/FPU-compatible 32-bit microcontroller with integrated analog front-end which achieves 0.1% precision without correction. It also offers three direct analog inputs for load cell, on-board thermistor, and an external thermocouple probe. The platform features an on-board humidity and temperature sensor, an ambient light/proximity sensor, and a real-time clock.

The Compagno (Italian for companion) board is a reference design for a multi-sensor wireless edge node offering a broad array of environmental sensing capabilities:

It also provides Wi-Fi and Bluetooth connectivity, NFC provisioning, and GPS position tracking, as well as direct cloud connectivity with the use of an optional plug-in cellular modem. The firmware source code enables easy integration of additional external sensors and simplifies design, prototyping and testing for industrial IoT applications such as condition monitoring, predictive maintenance and cloud connectivity.

The Avalanche board features a powerful FPGA with 300,000 logic elements and multiple very fast SERDES channels which also offers low power consumption.

The Avalanche board includes 4 Gbits of synchronous DDR3 DRAM memory, 64 Mbits of serial Flash, a Gigabit PHY interface, a Wi-Fi module, and multiple I/O interfaces to Arduino™, mikroBus™, Pmod™ and more. Two SERDES channels support an optional add-on SFP fiber optic transceiver module. Combined with an embedded programmer, USB interface and multiple ready-to-use project examples, the Avalanche board is an easy-to-use and affordable FPGA evaluation and development platform.

The Northern Lights kit provides an all-in-one demonstration platform for applications which perform machine learning and object recognition-based motor control. The Northern Lights platform combines video capture via an FPGA and color CMOS image sensor, a color OLED display, and a motor control board. It supports many artificial intelligence applications, including:

It is well suited to applications in the industrial, defense and automotive markets.

The Northern Lights kit includes an interactive demonstration project in which a hand-drawn digit is shown to the image sensor, is displayed in the OLED panel, and is automatically recognized. A robotic arm is then actuated to move an object to the corresponding digit location.

Be at the forefront of New Technology Innovations

Be at the forefront of New Technology Innovations

© 2024 Future Electronics. All rights reserved. Privacy | Terms & Conditions of Sale | Terms of Use | Accessibility